| |

|

|

|

Products > DC Inverter

Controller |

|

|

| |

MK

Series DC Inverter

Controller

Controlled Compressor Types:

DC Inverter Compressor

Rotary/Scroll

Power range: 1~10HP (1~3hp/

3~5hp/5~10Hp structures)

Propositional fan motor use

in system: DC Brushless type

Voltage default: 220/240V

50Hz 1phase (170~260V)

Available voltage: 115V/60Hz

1phase, 208-230V/60Hz 1phase

DC 300V

Ambient temperature range:

-10oC ~ 70oC

Compressor running speed

range: Programmed able by

user system

Temperature range:

Programmed able by user

system

Communication interface: Yes

Communication protocol: Yes

Safety Reference:

GB4706 (China) / IEC-EN60335

EMC: GB4343/CISPR14/EN55014

Certification or Approval

Reference:

ROHS/TUV/CCC/CE/ETL/CSA

MK10423

DC inverter Controller

cutsheet.pdf(699KB) MK10423

DC inverter Controller

cutsheet.pdf(699KB)

Please contact with Aislu

services team for all any

feature technical

information |

|

|

|

More Information

More Information

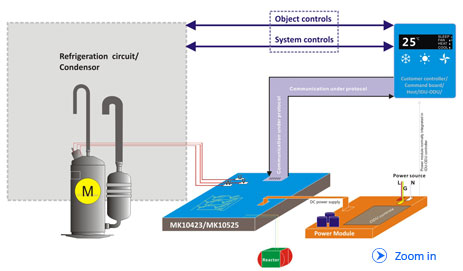

MK compressor driver is

focus on BLDC compressor

driving, the basically

principle as below:

A typical dc inverter air

conditioner or heat pump is

composed with fan motors,

bldc compressor, 4-way

valve, expansion valve,

temperature sensors, heat

exchangers...etc; Aislu

focus on provide customer

bldc driver for the bldc

compressor, original

equipment manufacturer

define system controls and

electric components controls

(object controls); equipment

manufacturer can make

controller call mk driver

with 0-5V compressor speed

adjustment signal or

communicate by asynchronism

protocol.

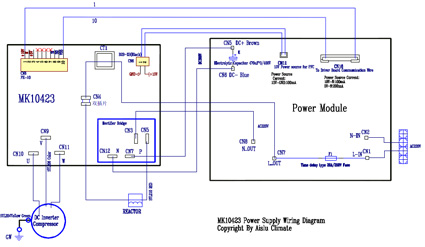

Its typical power and wiring

connection as below:

|

|

|

Integration of dc inverter

air conditioner/heat pump

system

Integration of dc inverter

air conditioner/heat pump

system

Aislu also help a/c or heat

pump manufacturing integrate

system controller, we work

as below process:

1) We require customer

provide a air conditioner

hardware sample, It is

meaning, Indoor unit

assembled (only without

PCB); Outdoor unit assembled

(only without PCB, but bldc

compressor installed)

2) We need study very

clearly for system

requirement, for example,

the PCB life, Safe

standards, EMC, EER, and A/C

unit program required. And

all other details

requirements(display,

dimension, protection,

temperature-frequency

point…)

3) Then, Aislu will open a

development contract to

customer to make everything

clearly on paper, and we

will charge a development

fee.

4) We will develop the dc

inverter a/c unit controller

for you upon the contract

and the development fee

received; normally the

development works need 30-45

days;

5) We setup everything well,

and then we install

controller on given sample,

and return to customer,

conduct safe tests, enthalpy

method performance tests,

working program tests…in

lab. And also can find the

bugs, or advise us where

need to modify. |

| |

|

|